+65 62241786

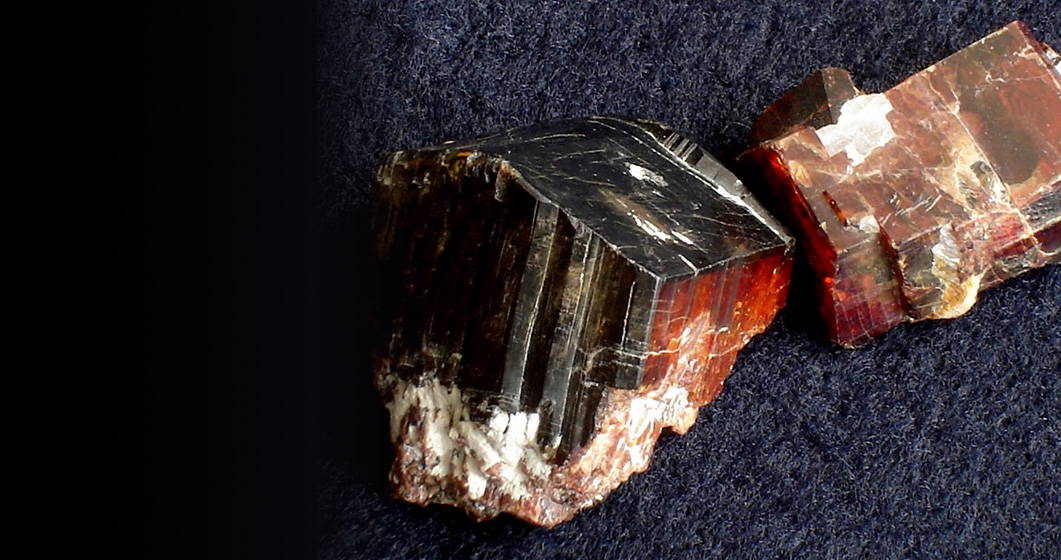

Coltan (short for columbite–tantalites and known industrially as tantalite) is a dull black metallic ore from which are extracted the elements niobium and tantalum.

The extraction and refining of Coltan, including the separation from niobium in these various tantalum-containing mineral concentrates, is generally accomplished by treating the ores with a mixture of hydrofluoric and sulfuric acids at elevated temperatures. This causes the Coltan and niobium values to dissolve as complex fluorides, and numerous impurities that were present also dissolve. Generally, the tantalum values in solution are converted into potassium tantalum fluoride (K2TaF7) or tantalum oxide (Ta2O5). The niobium is recovered as niobium oxide (Nb2O5) via neutralization of the niobium fluoride complex with ammonia to form the hydroxide, followed by calcination to the oxide.

The consolidation of metal powder for ingot and processing into various metallurgical products begins with either vacuum arc melting or electron beam melting of metal feedstocks, comprised of powder or high purity scrap where the elements with boiling points greater than tantalum are not present. Double and triple melt ingots achieve a very high level of purification with regard to metallics and interstitials. Ingots are used to produce the various metallurgical products named earlier. Ingot stock is also used for the production of such alloys as tantalum-10% tungsten. Ingot and pure tantalum scrap are used in the production of alloys for land and air-based turbines.